Global Well PCBA: Pioneering Innovation in PCB and PCBA Manufacturing

Introduction

In the ever-evolving landscape of electronics, the role of printed circuit boards (PCBs) and PCB assembly (PCBA) is crucial. As the demand for more advanced, reliable, and efficient electronic components grows, Global Well PCBA has emerged as a leader in the industry. Based in China, this manufacturer excels in PCB fabrication, PCB assembly, and the supply of electronic components, offering a range of advanced solutions designed to meet the complex needs of modern technology. This article delves into Global Well PCBA’s expertise, focusing on their technical capabilities, advanced PCB solutions, and the diverse applications of their products.

Mastery in PCB Fabrication

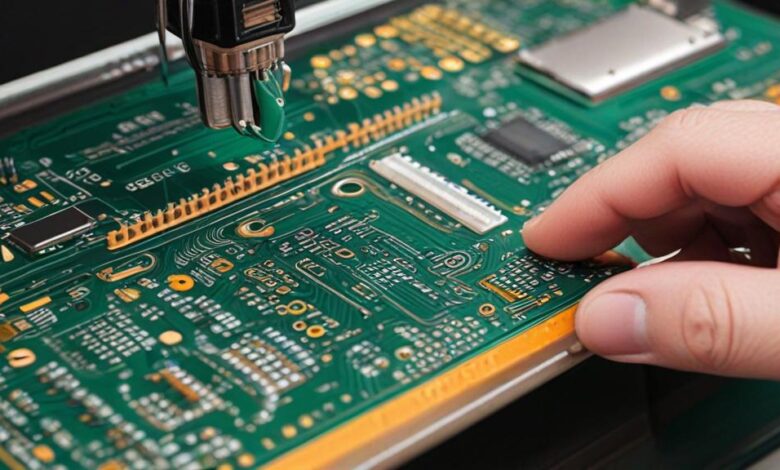

PCB fabrication is the foundation of Global Well PCBA operations. The process transforms raw materials into highly functional electronic boards that form the backbone of countless electronic devices. Here’s an in-depth look at their fabrication process:

– Design and Prototyping: The journey begins with design and prototyping. Global Well PCBA employs sophisticated Computer-Aided Design (CAD) software to create precise PCB layouts. These designs undergo rigorous simulations to ensure they meet all functional requirements and performance criteria. Prototyping allows for the testing of these designs in real-world conditions, making it possible to identify and rectify potential issues before full-scale production.

– Material Selection: Choosing the right materials is critical to the performance of PCBs. Global Well PCBA uses a variety of substrates, including traditional FR-4, high-frequency Rogers materials, and flexible polyimide films. Each material is selected based on the specific needs of the application, such as thermal performance, electrical characteristics, and mechanical strength.

– Manufacturing Processes: The fabrication process involves several key steps:

– Photoresist Application: A light-sensitive chemical layer is applied to the substrate, which will later define the circuit pattern.

– Etching: The unwanted copper is removed to leave behind the desired circuit pattern.

– Plating and Coating: Additional layers, such as solder masks and protective coatings, are applied to enhance durability and functionality.

– Drilling and Routing: Holes are drilled for component mounting and electrical connections, and the board is cut to its final shape.

Advanced PCB Solutions

Global Well PCBA is not just about traditional PCBs; they specialize in advanced solutions that push the boundaries of what PCBs can achieve. These include:

– Rigid-Flex PCBs: Rigid-Flex PCBs integrate both rigid and flexible substrates into a single board, offering a combination of durability and flexibility. This design is particularly beneficial in applications where space is limited or where the board needs to withstand mechanical stress. These PCBs are commonly used in aerospace, medical devices, and consumer electronics, where reliability and compact design are paramount.

– High Frequency PCBs: For applications involving high-speed signals and radio frequencies, High Frequency PCBs are essential. These boards use specialized materials that minimize signal loss and ensure high performance. Global Well PCBA’s High Frequency PCBs are used in telecommunications, radar systems, and high-speed digital circuits, providing the reliability needed for demanding applications.

Comprehensive PCB Assembly Services

PCB assembly is a critical step where the fabricated boards are populated with electronic components to create fully functional products. Global Well PCBA offers a range of assembly services:

– Surface Mount Technology (SMT): SMT is used to mount components directly onto the surface of the PCB. This method supports high-density component placement and is ideal for modern electronics where space is at a premium. Global Well PCBA utilizes advanced SMT equipment to ensure precision and efficiency.

– Through-Hole Technology (THT): THT involves inserting components through holes in the PCB and soldering them on the opposite side. This technique is well-suited for components that require strong mechanical connections, such as connectors and large capacitors. Global Well PCBA’s THT capabilities ensure robust and reliable assemblies.

– Hybrid Assembly: Combining both SMT and THT methods, hybrid assembly allows for flexibility in design and component placement. This approach is useful for complex designs that require a mix of different technologies, ensuring that all components are assembled efficiently and effectively.

Applications Across Industries

Global Well PCBA’s advanced PCB and PCBA solutions are utilized in a wide range of industries, each with its unique requirements:

– Telecommunications: In telecommunications, high-frequency PCBs are critical for maintaining signal integrity in devices such as routers, switches, and base stations. Global Well PCBA’s expertise in this area ensures that their PCBs meet the stringent demands of modern communication systems.

– Robotics: Robotics applications require PCBs that can endure harsh environments and deliver reliable performance. Rigid-Flex and High Frequency PCBs from Global Well PCBA are used in robotic control systems, sensors, and communication modules, contributing to the advancement of automation technology.

– Consumer Electronics: The consumer electronics sector demands high-performance PCBs for devices like smartphones, tablets, and wearables. Global Well PCBA’s ability to produce high-quality, durable PCBs supports the innovation and functionality of these popular products.

– Medical Devices: In the medical field, PCBs are used in diagnostic equipment, patient monitoring systems, and medical imaging devices. Global Well PCBA’s commitment to quality ensures that their PCBs meet the rigorous standards required for medical applications, providing reliability and accuracy in critical situations.

Commitment to Quality and Innovation

Global Well PCBA’s success is built on a foundation of quality and innovation. The company invests heavily in research and development to stay ahead of industry trends and technological advancements. Their commitment to quality is reflected in their stringent testing and quality control processes, which ensure that every PCB and PCBA meets the highest standards of performance and reliability.

Additionally, Global Well PCBA’s global reach and customer-centric approach allow them to provide tailored solutions that meet the specific needs of their clients. Whether it’s a high-frequency PCB for a telecommunications application or a Rigid-Flex board for a medical device, Global Well PCBA’s expertise and dedication to excellence make them a trusted partner in the electronics industry.

Conclusion

Global Well PCBA stands out as a leader in the PCB and PCBA manufacturing industry, offering advanced solutions and unparalleled expertise. Their capabilities in PCB fabrication, assembly, and electronic component supply position them as a key player in the development of cutting-edge technology. With a focus on Rigid-Flex and High Frequency PCBs, Global Well PCBA caters to diverse industries, including telecommunications, robotics, consumer electronics, and medical devices. Their commitment to quality, innovation, and customer satisfaction ensures that they remain at the forefront of the industry, driving the future of electronics.

Keep an eye for more news & updates on TechProMagazine!